Results

Results of the Soni-Laser Project

Mohamad Salimi, Ahmed Teyeb, Evelyne El Masri , Samiul Hoque, Phil Carr, Wamadeva Balachandran and Tat-Hean Gan

Published: 23 May 2024

Achievements and Findings Overview

- Contactless Transducers for PUVT (Power Ultra-Sound Vibration Treatment) were designed, tested and proved to work. This is the major achievement for Soni-Laser as this means PUVT is possible in production.

- Aluminium, to Aluminium, welds with PUVT are more than 10% stronger and have improved extension prior to fracture, in cases up-to 64% improved extension prior to fracture. Proved on all the aluminium grades normally used in battery interconnection.

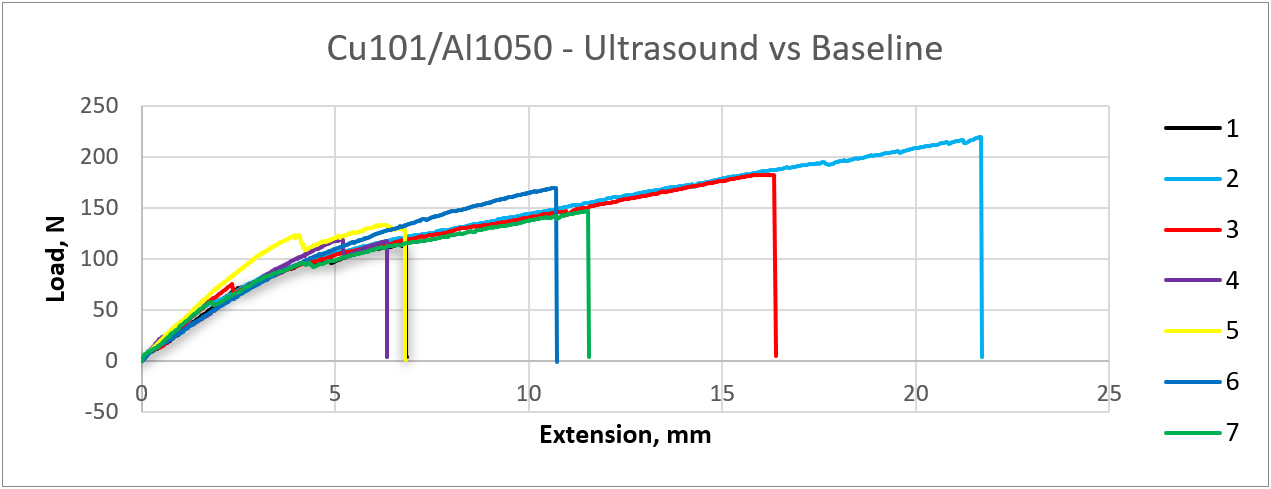

- Copper to Aluminium welds are more than 10% on average stronger and up-to 22% stronger in cases. PUVT improved the extension, but it is still not an advised weld for a battery/busbar connection. It’s too brittle and prone to fracture.

- Connection Impedance of Aluminium welds with PUVT showed a small reduction of impedance of typically 5%.

- SEM analysis shows in the copper/aluminium weld a more uniform composition in the aluminium rich region when applying ultrasounds.

- SEM analysis shows that the PUVT reduces the spread of the copper into the fusion zone, thus reducing the intermetallic compounds in the aluminium rich region.

Pull Test (Peel)

Copper to Aluminium

The welding of Copper to Aluminium connections is highly sought-after due to the increase in demand of efficient power transfer between battery and vehicle. However, the joining of dissimilar materials like Copper to Aluminium you are faced the formation of brittle intermetallic compounds (IMC’s). The use of Power Ultrasonic Vibration Treatment (PUVT) when laser welding has proven to refine the grain structure, disrupt the epitaxial growth of dendrites and transform the shapes of IMC’s when welding Aluminium 6082 (www.ultramat.co.uk). Using the PUVT technology this paper aims to achieve similar results in an attempt to improve the ductility and strength of Copper to Aluminium joints.

To test for improvement in the strength and ductility, peel tests were carried out on welded copper to aluminium joints. A series of trials using different configuration, frequencies and powers of ultrasound were compared with each other and baseline results. Below you will find the effect of a PUVT on the load vs extension.

Frequency, kHz |

Transducer Type |

Placement/Angle |

Average Extension, mm |

Extension Analysis |

Extension Rank |

Average Load, N |

Load Analysis |

Load Rank |

|

1 |

Baseline |

N/a |

N/a |

4.8 |

100.0% |

6 |

110.0 |

100.0% |

7 |

2 |

20 |

Taper Horn |

Contactless on the spot |

20.8 |

431.6% |

1 |

246.8 |

224.4% |

1 |

3 |

20 |

Needle 20% |

Contactless on the spot |

11.9 |

246.5% |

2 |

170.8 |

155.3% |

2 |

4 |

28 |

Focused |

Contactless on the Spot/45Deg |

6.5 |

135.1% |

5 |

112.2 |

102.1% |

6 |

5 |

28 |

Taper |

Contactless on the Spot/45Deg |

4.7 |

98.3% |

7 |

124.3 |

113.0% |

5 |

6 |

40 |

Focused |

Contactless on the Spot/45Deg |

10.7 |

221.0% |

3 |

170.1 |

154.7% |

3 |

7 |

40 |

Taper |

Contactless on the Spot/45Deg |

7.1 |

147.4% |

4 |

137.8 |

125.2% |

4 |

Conclusion

- Pull test shows improvement to the strength and ductility

- Evidence from the macros, shows good conditions for 30% US power at medium frequency

- Evidence of over cavitation in high US power as seen with Al3003 and Al1050

- The hardness of the alloy produced will render the weld unsuccessful

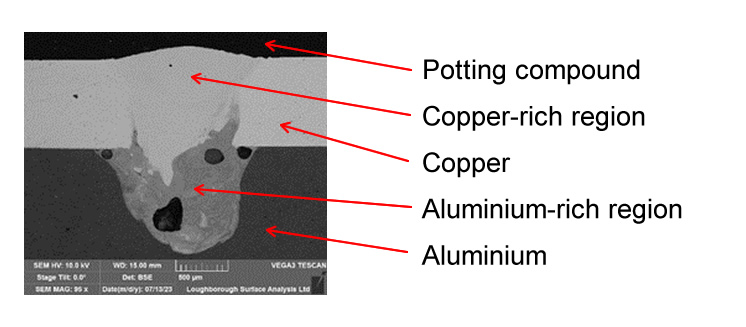

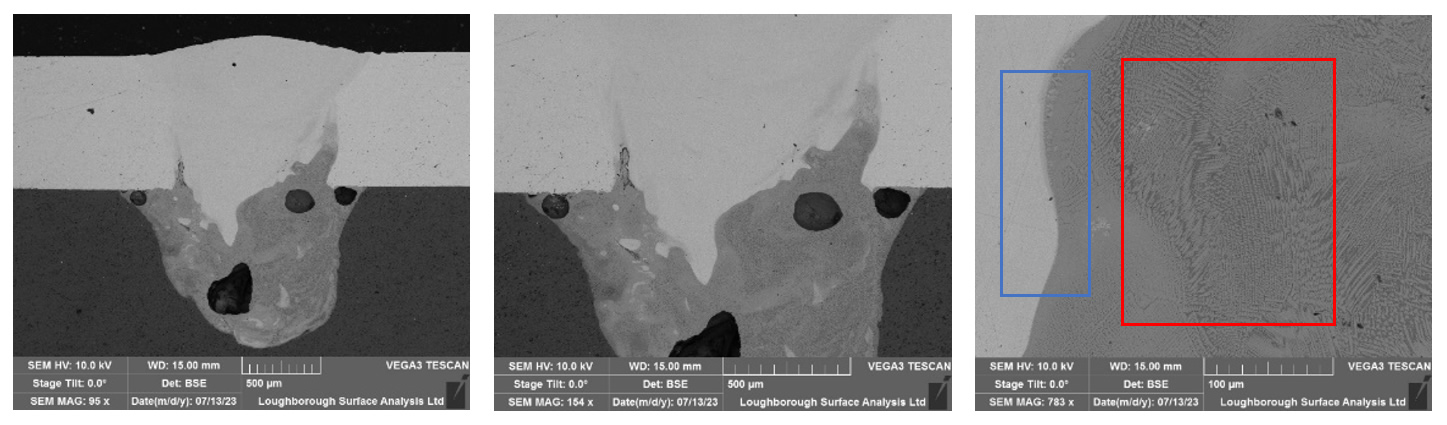

SEM and EDX Analysis Results.

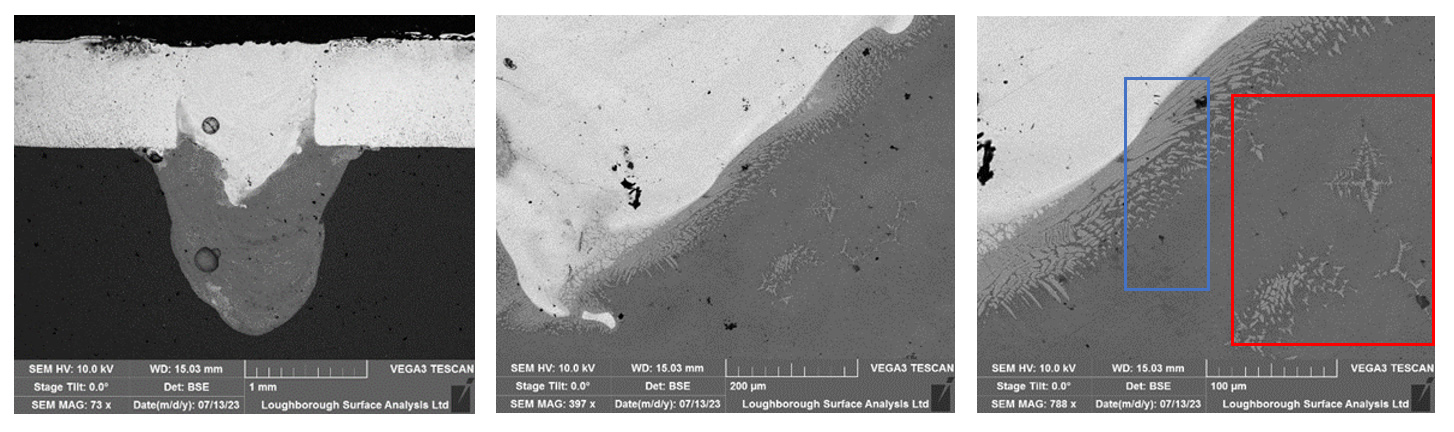

Macro of copper to aluminium weld explained

Without Ultrasound

With PUVT (Power Ultra-sonic Vibration Treatment)

Conclusion

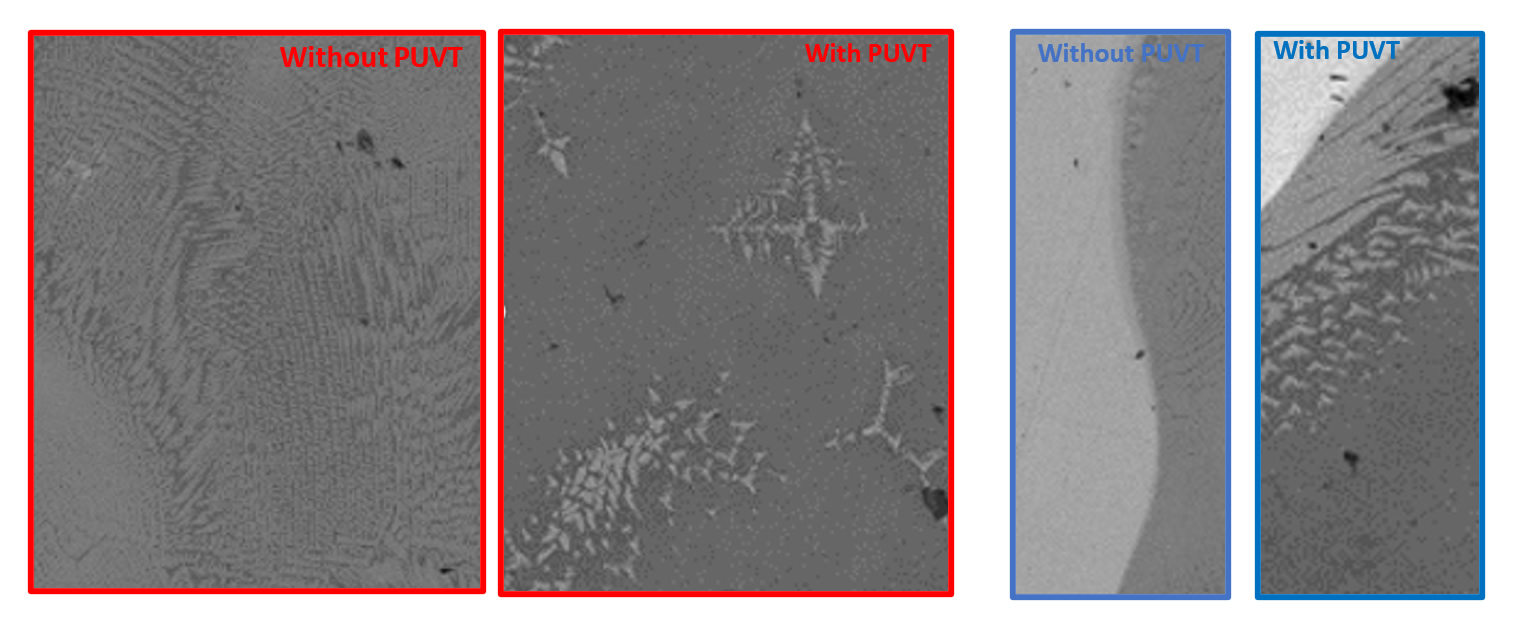

The image above shows that in the sample with PUVT the intermetallic compounds form around the interface between the copper rich and aluminium rich zone and doesn’t spread to the aluminium rich zone. Whereas, with the sample without PUVT the intermetallic compounds are formed in the Aluminium rice zone.

Without PUVT

With PUVT

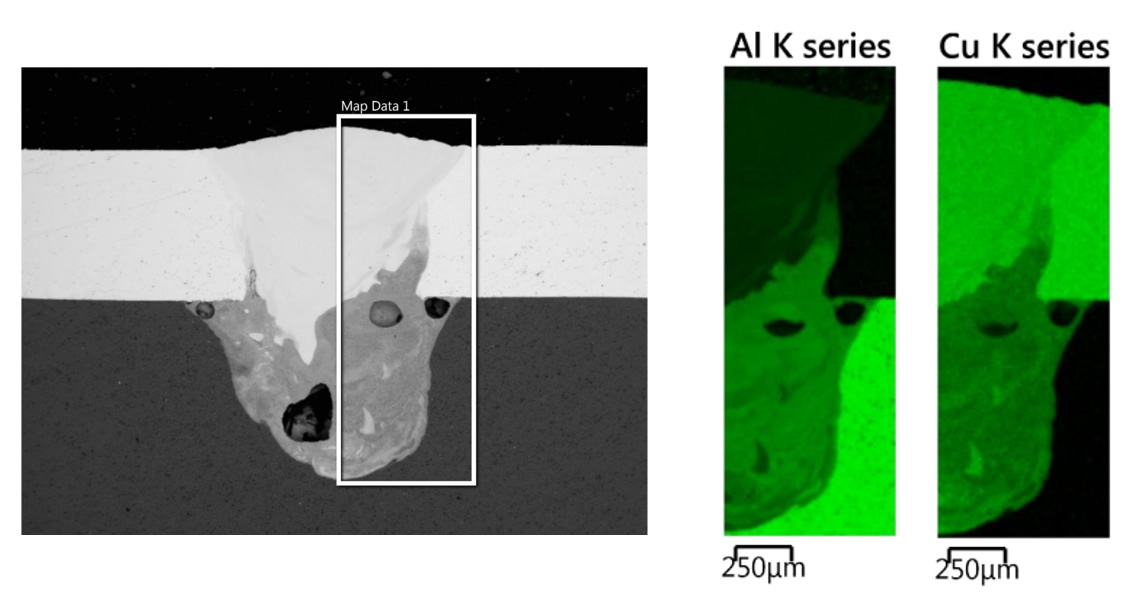

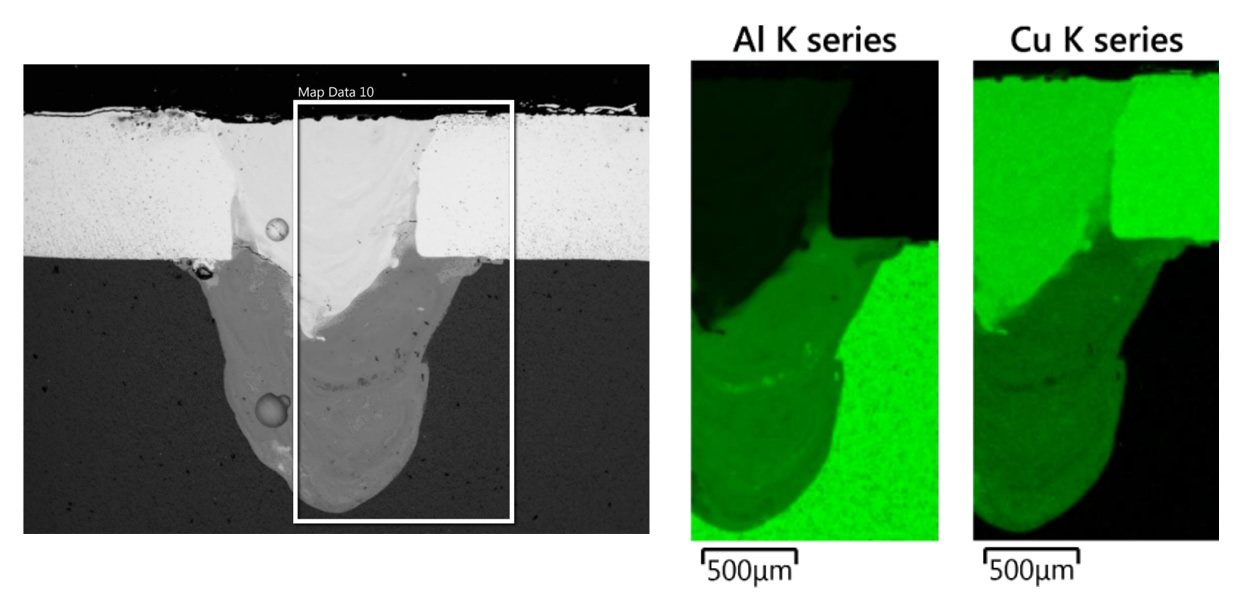

The EDX images above show the effect of using PUVT, the copper from the copper rich region does not spread into the aluminium rich region. This significantly reduces the intermetallic compounds found in the aluminium rich region.

Soni-Laser Project Reference: 10018077

Innovate UK is the UK’s innovation agency

Innovate UK is an executive non-departmental public body, sponsored by the Department for Business, Energy & Industrial Strategy.